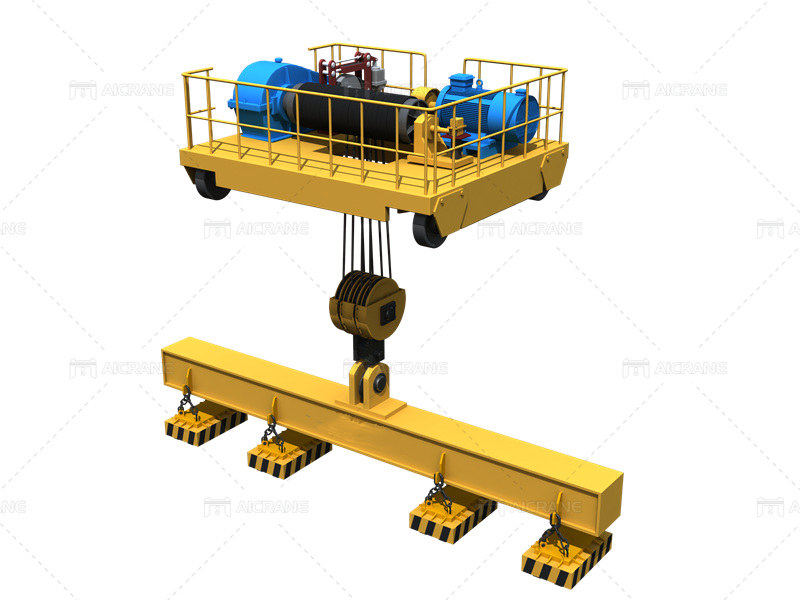

Magnetic cranes, also known as electromagnets, use magnetic fields to lift and move heavy loads. They are used in various industries, including scrap metal recycling, construction, and manufacturing, to handle ferromagnetic materials, such as iron and steel. These cranes have several advantages over traditional cranes, making them an ideal choice for many material handling applications.

One of the main benefits of magnetic cranes is their versatility. They can handle a number of ferromagnetic materials, including scrap metal, steel plates, and even heavy machinery. This is what ordinary single-girder overhead cranes and double-girder overhead cranes(двухбалочный мостовой кран) cannot do. This versatility makes magnetic cranes ideal for scrap metal recycling facilities, construction sites, and manufacturing plants, where they can handle different materials.

Another benefit of magnetic cranes(магнитный кран) is their speed and efficiency. Magnetic cranes can quickly and easily pick up and move heavy loads, making them ideal for handling materials that must be moved quickly, such as scrap metal or other waste materials. They also have a high level of precision, allowing them to handle delicate loads without causing damage. Magnetic cranes are ideal for moving heavy machinery and other fragile loads requiring careful handling.

In terms of safety, magnetic cranes are designed to be safe and reliable. They are equipped with safety features, such as load limiters, which prevent the crane from picking up more material than it can safely handle. They also have multiple braking systems, which ensure that the crane can be stopped quickly in an emergency. Additionally, magnetic cranes are equipped with advanced control systems, which allow for precise and efficient handling of the material being transported.

Magnetic cranes are also low maintenance compared to other types of cranes, such as explosion-proof cranes, grab cranes(грейферный кран). They are designed to handle heavy-duty operations and are built with durable materials that are resistant to wear and tear. However, regular maintenance is still necessary to ensure the crane remains in good working order. This includes regular inspections of the crane and its components, as well as regular maintenance and repairs as needed.

In terms of operation, magnetic cranes are relatively easy to operate. They are equipped with control systems that are straightforward and user-friendly, making it easy for operators to quickly and efficiently handle the material being transported. Additionally, many magnetic cranes are designed with ergonomic features, such as comfortable operator cabins, which ensure that the operator can work safely and efficiently for extended periods.

Finally, magnetic cranes are environmentally friendly. They do not produce emissions or generate waste, making them an ideal choice for use in areas facing climate change problems. Moreover, you can use them to recycle ferromagnetic materials, such as scrap metal, which reduces waste and helps to conserve natural resources.

The Bottom Line

Magnetic cranes use magnetic fields to lift and move heavy loads from one point to another. They are versatile, efficient, safe, low maintenance, and easy to operate, making them an ideal choice for a wide range of material handling applications. Whether you are handling scrap metal, heavy machinery, or any other ferromagnetic material, a magnetic crane can provide a cost-effective and efficient solution for your material handling needs.

Aicrane is one of the reputable lifting machine manufacturers(завод кранов) in China with more than 10 years’ experience in crane designing, manufacturing and installation. Our overhead cranes have been exported to over 80 countries and regions such as Pakistan, Vietnam, Russia, Australia and Tanzania.