Crushing stations are vital in mining, construction, and recycling industries. They break down rocks into usable sizes. However, the harsh nature of this work can wear down equipment quickly. Therefore, selecting wear-resistant materials is essential for longevity. Understanding the importance of these materials can save time and money.

Understanding Crusher Types

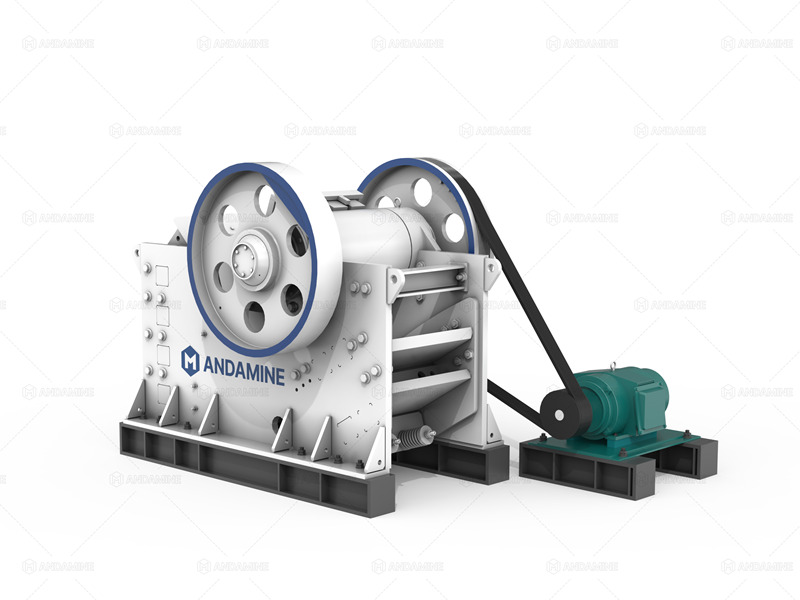

Different crushers serve various purposes. Jaw crusher, cone crusher, and impact crusher each have unique roles. Jaw crushers crush large rocks with a compressive force. They are suitable for primary crushing. Cone crushers, on the other hand, excel in secondary and tertiary crushing. They reduce material size further. Impact crushers, meanwhile, use high-speed impact force. They are ideal for producing finer particles.

Importance of Wear-Resistant Materials

Wear-resistant materials extend the life of crusher equipment. They withstand abrasive forces better than standard materials. This durability reduces downtime and maintenance costs. Moreover, selecting the right materials enhances the efficiency of crushers. This increases productivity and ensures consistent output quality.

Materials for Jaw Crushers

Jaw crushers require robust materials to handle large rocks. Manganese steel is a popular choice. It offers high impact strength and abrasion resistance. This durability is crucial for the crushing jaw plates. Additionally, some jaw crushers use tungsten carbide inserts. These inserts provide extra hardness for tough materials.

Materials for Cone Crushers

A cone crusher needs materials that can withstand high pressure. Chrome-molybdenum steel is often used. It offers excellent tensile strength and resistance to wear. This material ensures the longevity of cone crusher mantles and liners. Furthermore, ceramic composites offer added protection. They enhance wear resistance in high-stress areas.

Materials for Impact Crushers

Impact crushers rely on materials that can endure repeated impacts. Martensitic steel is a common choice. It provides a good balance of hardness and toughness. Additionally, chromium steel offers enhanced wear resistance. It is ideal for impact crusher blow bars and liners. Using these materials increases the lifespan of impact crushers significantly.

Factors to Consider When Selecting Materials

Several factors influence material selection. First, consider the type of material being processed. Harder materials require stronger wear-resistant materials. Second, analyze the crusher’s operating conditions. High temperatures or corrosive environments impact material choice. Lastly, consider cost and availability. While high-end materials last longer, they may not always fit the budget.

Benefits of Using Wear-Resistant Materials

Using wear-resistant materials offers numerous benefits. Firstly, they reduce equipment downtime. Longer-lasting materials mean fewer replacements and repairs. Secondly, they enhance operational efficiency. Consistent performance leads to better productivity. Lastly, they improve safety. Durable materials minimize the risk of equipment failure, ensuring a safer work environment.

Conclusion

In conclusion, selecting wear-resistant materials is crucial for the longevity of crushing station equipment. Understanding the specific needs of jaw crushers, cone crushers, and impact crushers helps in making informed choices. Wear-resistant materials not only extend equipment life but also enhance efficiency and safety. By considering factors like material type, operating conditions, and cost, companies can optimize their crushing operations. Investing in the right materials today can lead to significant savings and improved performance in the long run.