Hydraulic mooring winches serve as critical components in maritime operations, providing the power and precision needed to secure vessels to docks or other structures. The proper installation of these winches is paramount to ensuring their optimal performance, reliability, and safety. In this article, we will explore comprehensive guidelines for the installation of hydraulic mooring winches, covering key considerations to enhance their functionality and longevity.

Site Assessment and Planning:

Before commencing the installation of hydraulic mooring winches, a thorough site assessment must be conducted. Factors such as the type of vessels to be moored, environmental conditions, and available power sources should be carefully considered. Additionally, a detailed plan outlining the placement of winches, hydraulic lines, and control systems should be developed to optimize efficiency and minimize potential issues during installation.

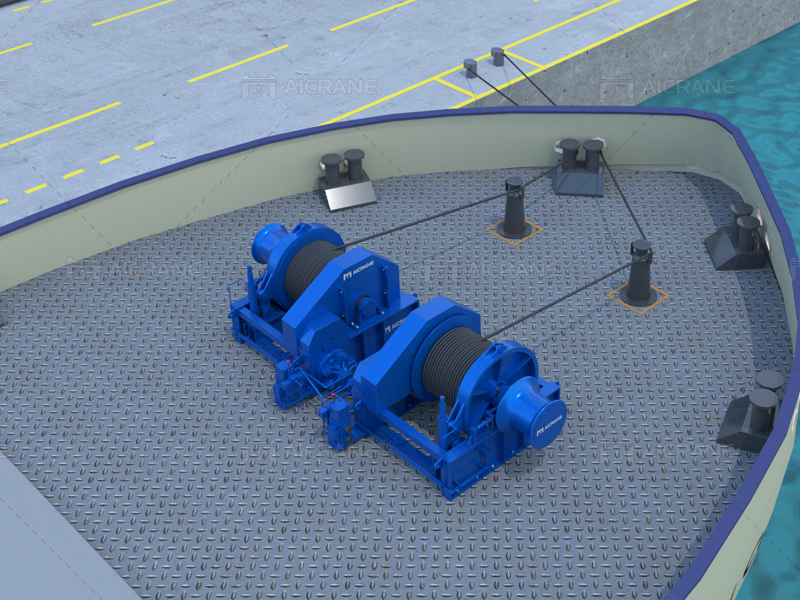

Foundation Preparation:

The foundation on which hydraulic mooring winches are mounted is crucial for their stability and longevity. The foundation must be solid, level, and capable of withstanding the dynamic loads generated during mooring operations. Proper reinforcement of the foundation is essential, considering factors such as soil conditions and seismic considerations in regions prone to earthquakes.

Alignment and Leveling:

Accurate alignment and leveling of hydraulic mooring winches are critical for their effective operation. Deviations from the specified alignment can lead to increased wear and tear, reduced efficiency, and potential safety hazards. Precision instruments should be used during the installation process to ensure that the winches are aligned with the mooring points and leveled to perfection.

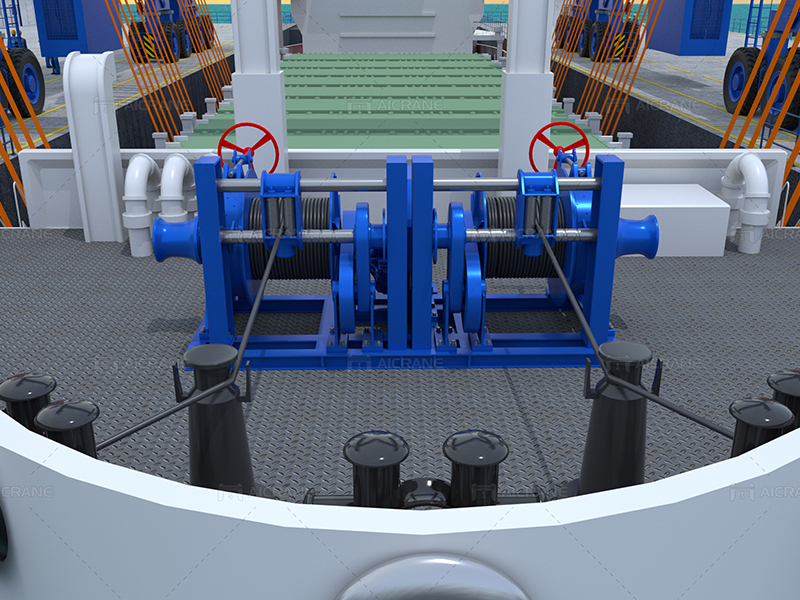

Hydraulic System Installation:

The hydraulic system is the powerhouse of mooring winches, and its installation requires meticulous attention to detail. Hydraulic lines must be installed with precision, avoiding sharp bends or kinks that could impede the flow of hydraulic fluid. Proper fittings, seals, and connectors should be used to prevent leaks, and the hydraulic reservoir should be positioned to facilitate easy access for maintenance.

Power Source Compatibility:

Ensuring compatibility with the power source is paramount for hydraulic mooring winches. The power supply must meet the specified requirements outlined by the manufacturer. Voltage stability, current capacity, and frequency must align with the winch’s specifications to guarantee optimal performance and prevent damage to the hydraulic system.

Control System Integration:

The control system of hydraulic mooring winches is central to their precise operation. During installation, it is crucial to integrate the control system seamlessly with the hydraulic components. This includes connecting sensors, actuators, and the central control unit. Thorough testing of the control system should be conducted to identify and address any issues before the mooring winches are put into active service.

Safety Measures:

The installation of hydraulic mooring winches should prioritize safety at every step. Adequate safety measures, such as emergency stop mechanisms, should be integrated into the control system. Additionally, clear signage and safety barriers should be installed to alert personnel to the operational areas of the winches, reducing the risk of accidents during installation and subsequent use.

Environmental Considerations:

Hydraulic mooring winches often operate in challenging environmental conditions, including exposure to saltwater and varying temperatures. To enhance the winch’s resilience, corrosion-resistant materials should be used during installation. Protective coatings and regular maintenance practices, such as freshwater rinses, can further safeguard the winch against environmental stress.

Load Testing:

Before putting hydraulic mooring winches into active service, thorough load testing should be conducted. This involves subjecting the winches to loads that simulate real-world mooring scenarios. Load testing ensures that the winches can handle the expected loads without compromising safety or efficiency. Any issues identified during testing should be promptly addressed before the winches are declared operational.

Documentation and Training:

Comprehensive documentation of the installation process is essential for future reference and maintenance. This includes detailed schematics, specifications, and a log of all installation activities. Furthermore, personnel involved in the operation and maintenance of hydraulic mooring winches should undergo thorough training to ensure that they are well-equipped to handle the equipment safely and effectively.

Regular Maintenance Schedule:

The proper installation of hydraulic mooring winches sets the foundation for their long-term performance. However, ongoing maintenance is equally crucial. Establishing a regular maintenance schedule that includes inspections, lubrication, and component replacements as needed is essential. This proactive approach enhances the lifespan of the winches and minimizes the risk of unexpected failures.

Conclusion:

In the dynamic world of maritime operations, the proper installation of hydraulic mooring winches is a cornerstone for success. Adhering to these comprehensive guidelines ensures that these critical components operate at their peak efficiency, providing a secure and reliable mooring solution. From site assessment and planning to ongoing maintenance, each step in the installation process plays a vital role in the overall performance and safety of hydraulic mooring winches. As technology advances and industry standards evolve, these guidelines serve as a foundation for navigating the complexities of installing hydraulic mooring winches in diverse maritime environments. To learn more, visit https://steelmillcranes.com/