The installation of a 50 ton gantry crane is a complex and critical undertaking that demands meticulous planning, precision engineering, and unwavering commitment to safety. Whether it’s for heavy-duty industrial applications, shipyards, or construction projects, the successful installation of such a powerful crane requires a strategic approach. In this comprehensive guide, we will explore the key steps and considerations involved in the installation of a 50 ton gantry crane.

Preliminary Planning and Site Assessment

The journey of installing a 50 ton gantry crane begins with a thorough preliminary planning phase. This involves a comprehensive site assessment to evaluate the terrain, foundation conditions, and spatial constraints. Engineers must consider factors such as ground stability, load-bearing capacity, and potential environmental challenges. The data gathered during this phase informs crucial decisions regarding the type of gantry crane, foundation requirements, and the optimal location for installation.

Foundation Design and Construction

A robust foundation is the cornerstone of a safe and stable gantry crane installation. The design and construction of the foundation are engineered to withstand the crane’s dynamic loads and ensure minimal deflection during operation. Factors such as soil analysis, foundation type (concrete or steel), and load distribution are carefully considered. Reinforcement measures may be implemented to enhance the foundation’s strength, aligning with industry standards and specific project requirements.

Structural Assembly and Component Installation

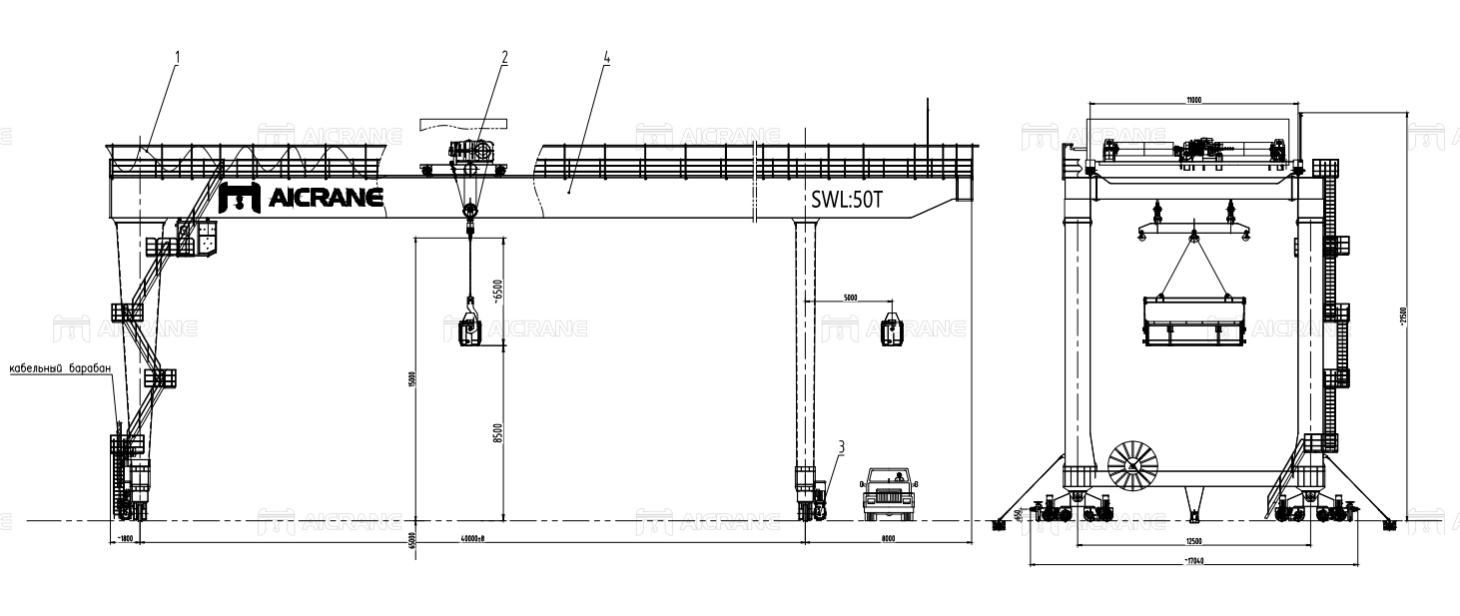

Once the foundation is in place, the structural assembly of the gantry crane takes center stage. This involves the installation of key components, including the main girder, legs, crossbeams, and end trucks. The precision alignment of these components is critical to achieving optimal performance and load distribution. Engineers and technicians work collaboratively to ensure that each element is securely fitted and aligned according to the specifications of gantry crane manufacturer.

Mechanical and Electrical Installation

The mechanical and electrical installation phases are intricate processes that demand specialized expertise. The hoisting and trolley systems, along with the electrical control panels, are meticulously installed and integrated into the crane structure. Wiring, sensors, and safety features are calibrated to function seamlessly. Regular inspections and tests are conducted to verify the proper functioning of these systems, emphasizing compliance with safety standards and operational efficiency.

Load Testing and Calibration

Load testing is a critical step in the installation process, providing empirical evidence of the crane’s structural integrity and load-bearing capacity. The crane undergoes a series of controlled load tests, simulating real-world operating conditions. Engineers monitor parameters such as deflection, hoisting speed, and braking performance. Calibration adjustments are made as needed to ensure that the crane meets or exceeds its specified load capacity while maintaining safety margins.

Safety Protocols and Operator Training

Ensuring the safety of personnel and equipment is paramount in the installation of a 50 ton gantry crane. Rigorous safety protocols are implemented, including the use of personal protective equipment, fall protection measures, and adherence to lockout/tagout procedures. Operator training programs are conducted to familiarize personnel with the crane’s controls, emergency procedures, and safe operating practices. Ongoing safety awareness and training initiatives contribute to a culture of safety that permeates the entire operation.

Commissioning and Handover

The commissioning phase marks the culmination of the installation process, transitioning the gantry crane from a construction project to a fully operational asset. Engineers conduct final checks, system verifications, and functional tests to ensure that all components operate harmoniously. Once satisfied with the crane’s performance, the project is formally handed over to the client. This phase often involves the transfer of technical documentation, maintenance guidelines, and ongoing support to ensure the client’s seamless integration of the crane into their operations.

The installation of a 50 ton gantry crane is a multifaceted undertaking that demands a blend of engineering expertise, precision execution, and unwavering commitment to safety. From preliminary planning and foundation design to structural assembly, mechanical and electrical installation, load testing, safety protocols, and commissioning, each step contributes to the crane’s successful integration into industrial or construction operations. A well-executed installation not only ensures the crane’s optimal performance but also establishes the foundation for a safe and productive working environment for years to come.